Unlocking Superior Performance Through Display Customization

In today's rapidly evolving technological landscape, the choice of display technology can make or break the success of your product. Custom LCD solutions have emerged as a game-changing option for businesses seeking to optimize their applications and stand out in competitive markets. When you select a custom LCD, you're not just choosing a display – you're investing in a tailored solution that perfectly aligns with your specific requirements and enhances your product's overall value proposition.

The decision to implement a custom LCD solution represents a strategic approach to product development that goes beyond mere functionality. It encompasses considerations of user experience, operational efficiency, and long-term sustainability. As we explore the numerous advantages of custom LCD technology, you'll discover how these specialized displays can transform your application's performance and market position.

Design Flexibility and Application-Specific Optimization

Tailored Form Factors and Mechanical Integration

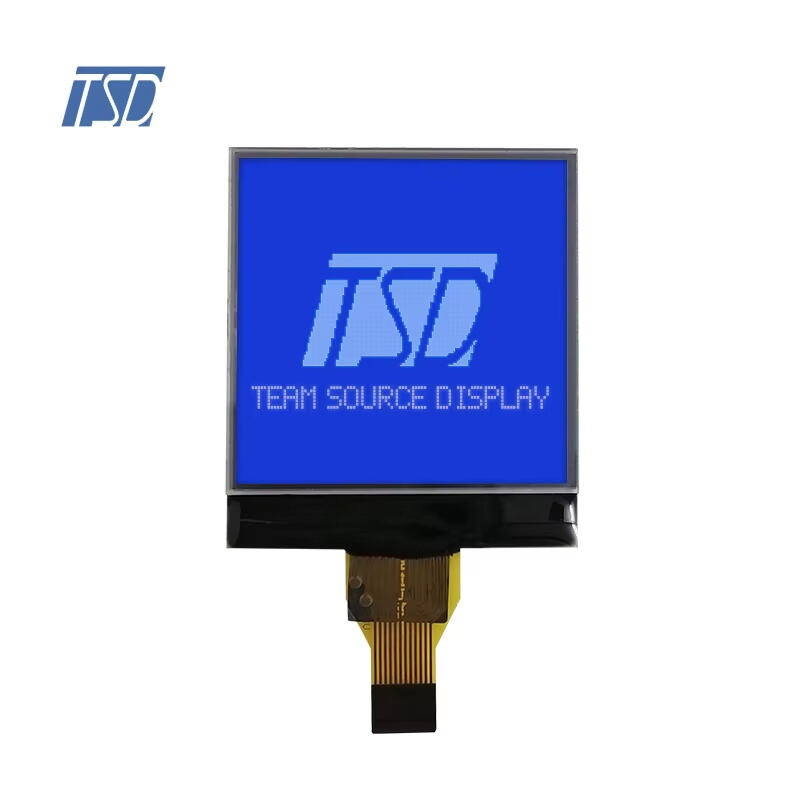

Custom LCD solutions offer unprecedented flexibility in terms of physical dimensions and mounting options. Engineers can specify exact screen sizes, aspect ratios, and thickness requirements that perfectly match their application's space constraints. This level of customization ensures seamless integration into existing product designs without compromising on functionality or aesthetics.Like Segment Graphic Monochrome LCD Display,you can customize various sizes to meet your needs.

The ability to define custom mounting brackets, bezels, and connection interfaces means that your display solution can be optimized for both assembly efficiency and end-user serviceability. This thoughtful integration can significantly reduce manufacturing complexities and associated costs while improving the overall product reliability.

Enhanced Visual Performance Parameters

When selecting a custom LCD, you gain control over critical display parameters that directly impact user experience. From brightness levels and contrast ratios to viewing angles and color reproduction, every aspect can be fine-tuned to meet specific application requirements. This level of optimization ensures optimal visibility across various lighting conditions and usage scenarios.

Furthermore, custom LCD solutions allow for the integration of specialized optical films and surface treatments that can enhance readability, reduce glare, and improve durability. These customizations prove particularly valuable in challenging environments where standard displays might fall short of performance requirements.

Environmental Adaptability and Durability

Temperature and Humidity Resistance

Custom LCD displays can be engineered to withstand extreme temperature variations and humidity levels that would typically compromise standard display solutions. This enhanced environmental tolerance makes them ideal for outdoor installations, industrial environments, and applications exposed to challenging weather conditions.

Through careful selection of components and materials, custom LCDs can maintain consistent performance across wide temperature ranges, ensuring reliable operation in both freezing cold and scorching heat. This robustness translates to reduced maintenance requirements and extended product lifecycles.

Ruggedized Design Features

The ability to incorporate specialized protective features into custom LCD designs significantly enhances their durability and reliability. From reinforced glass overlays to shock-absorbing mounting systems, these displays can be built to withstand physical impacts, vibrations, and other mechanical stresses.

Additional protective measures such as conformal coatings and sealed enclosures can be implemented to guard against dust, moisture, and chemical exposure. These features make custom LCDs particularly suitable for use in harsh industrial environments, medical equipment, and military applications.

Power Efficiency and Thermal Management

Optimized Power Consumption

Custom LCD solutions offer significant advantages in terms of power efficiency through targeted optimization of backlight systems and driving electronics. By matching illumination levels to specific application requirements, power consumption can be minimized without compromising display performance.

Advanced power management features can be incorporated to enable dynamic brightness control and selective display activation, further reducing energy consumption in battery-powered applications. This optimization extends operational runtime and reduces heat generation, contributing to improved system reliability.

Thermal Design Considerations

The ability to implement application-specific thermal management solutions in custom LCD designs helps ensure stable operation across varying environmental conditions. Heat dissipation paths can be optimized through careful component placement and the integration of thermal management features.

Custom LCDs can incorporate specialized heat-spreading materials and cooling solutions that maintain optimal operating temperatures while minimizing the impact on overall system design. This attention to thermal management contributes to extended component lifetime and improved display performance stability.

Long-term Availability and Support

Supply Chain Security

Opting for a custom LCD solution provides greater control over component availability and supply chain management. Unlike standard displays that may face unexpected obsolescence, custom solutions can be designed with long-term availability in mind, incorporating components with guaranteed production lifecycles.

This approach helps protect against supply chain disruptions and ensures consistent product availability throughout your application's intended market life. Additionally, working with a dedicated custom LCD manufacturer often includes provisions for lifetime buy options and component storage programs.

Technical Support and Documentation

Custom LCD projects typically come with comprehensive technical support and documentation packages that facilitate smooth integration and long-term maintenance. Detailed specifications, interface guidelines, and troubleshooting procedures ensure that your engineering team has all necessary resources for successful implementation.

Ongoing technical support from the display manufacturer helps address any issues that may arise during product development and deployment, reducing time-to-market and minimizing potential disruptions to your production schedule.

Frequently Asked Questions

How long does it take to develop a custom LCD solution?

The development timeline for a custom LCD typically ranges from 12 to 20 weeks, depending on the complexity of requirements and the extent of customization needed. This timeline includes design specification, prototype development, testing, and production setup phases.

What are the minimum order quantities for custom LCD displays?

Minimum order quantities vary based on the complexity of the custom LCD design and manufacturer capabilities. Typical MOQs range from 500 to 1,000 units for initial production runs, with potential for lower quantities during development and prototyping phases.

How does the cost of custom LCDs compare to standard displays?

While initial development costs for custom LCDs are higher than standard displays, the total cost of ownership often proves more favorable when considering factors such as optimal performance, reduced integration costs, longer product lifecycles, and improved reliability. Volume production costs typically become competitive with standard solutions once program requirements are met.