Modern vehicles have transformed from simple mechanical machines into sophisticated technological platforms that rely heavily on advanced display systems. At the heart of these digital interfaces lies the LCD module, a crucial component that enables everything from dashboard instrumentation to entertainment systems. These specialized display units have become indispensable in contemporary automotive design, providing drivers and passengers with essential information while enhancing the overall driving experience through intuitive visual interfaces.

The automotive industry has witnessed unprecedented technological advancement over the past decade, with display technology serving as a primary catalyst for innovation. Vehicle manufacturers now integrate multiple LCD modules throughout their designs, creating seamless digital ecosystems that connect various automotive functions. From basic speedometer displays to complex infotainment centers, these modules serve as the primary communication channel between the vehicle and its occupants, delivering critical information in real-time while maintaining optimal visibility under diverse lighting conditions.

Understanding the significance of LCD modules in modern vehicles requires examining their multifaceted applications and the technical specifications that make them suitable for automotive environments. These components must withstand extreme temperatures, vibrations, and electromagnetic interference while maintaining consistent performance standards. The evolution of automotive display technology has created new opportunities for enhanced safety features, improved user experiences, and greater integration with mobile devices and cloud-based services.

Fundamental Technology Behind Automotive LCD Modules

Core Display Technologies and Manufacturing Processes

Automotive LCD modules utilize liquid crystal display technology specifically engineered for vehicular applications, incorporating advanced backlighting systems and polarization filters that ensure optimal visibility regardless of ambient lighting conditions. The manufacturing process involves precision assembly of multiple layers, including the liquid crystal cell, color filters, and protective substrates that collectively create a durable display capable of withstanding automotive environmental stresses. Modern automotive LCD modules employ In-Plane Switching technology, which provides superior viewing angles and color accuracy compared to traditional Twisted Nematic displays.

The construction of automotive LCD modules requires specialized materials that can operate effectively within the temperature ranges commonly encountered in vehicles, typically from negative forty to positive eighty-five degrees Celsius. Anti-reflective coatings and enhanced brightness capabilities ensure that critical information remains visible even under direct sunlight, while electromagnetic compatibility measures prevent interference with other vehicle electronic systems. Quality control processes during manufacturing involve extensive testing protocols that simulate various automotive conditions to guarantee long-term reliability and performance consistency.

Advanced Features and Technical Specifications

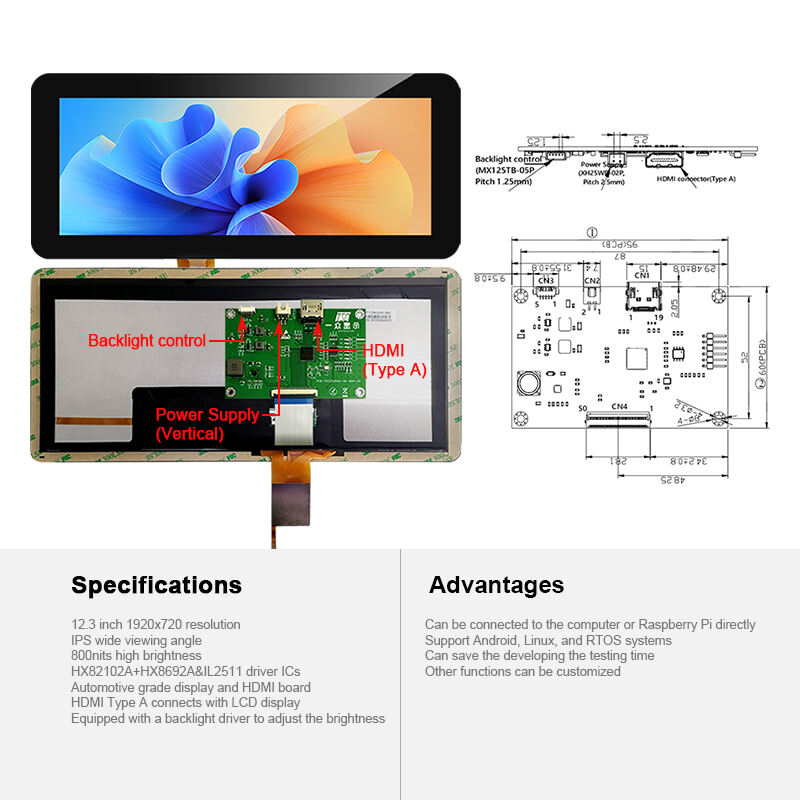

Contemporary automotive LCD modules incorporate sophisticated features such as capacitive touch interfaces, high-definition resolution capabilities, and rapid response times that enhance user interaction and system responsiveness. These modules often support multiple input formats, including HDMI, USB, and wireless connectivity options that enable seamless integration with smartphones and other mobile devices. The integration of touch-sensitive surfaces eliminates the need for physical buttons while providing intuitive control mechanisms that can be easily operated while driving.

Resolution specifications for automotive LCD modules have evolved significantly, with many current models supporting Full HD or even higher resolutions that ensure crisp, clear display of text, graphics, and video content. Color reproduction accuracy remains crucial for applications such as navigation systems and rear-view camera displays, where precise color representation can impact safety and usability. Advanced LCD modules also incorporate ambient light sensors that automatically adjust brightness levels based on surrounding conditions, reducing eye strain and optimizing power consumption.

Critical Applications in Modern Vehicle Systems

Dashboard and Instrument Cluster Integration

The primary application of LCD Module technology in vehicles centers around dashboard instrumentation, where digital displays have largely replaced traditional analog gauges and mechanical indicators. These sophisticated display systems present speedometer readings, fuel levels, engine diagnostics, and navigation information in customizable formats that can be tailored to individual driver preferences. The flexibility of LCD modules allows manufacturers to create dynamic interfaces that adapt based on driving modes, vehicle conditions, and user settings.

Modern instrument clusters utilizing LCD modules can display multiple information layers simultaneously, switching between different views based on priority and context. For example, during normal driving conditions, the display might show standard speedometer and fuel information, but during navigation, it can expand to include turn-by-turn directions and traffic updates. This adaptability enhances the driving experience while maintaining focus on essential information without overwhelming the driver with unnecessary details.

Infotainment and Communication Systems

Infotainment systems represent another crucial application area where LCD modules serve as the primary interface for entertainment, communication, and connectivity features within modern vehicles. These large-format displays typically range from seven to fifteen inches and support touch-based interaction for controlling audio systems, climate controls, and vehicle settings. The integration of smartphone connectivity protocols such as Apple CarPlay and Android Auto requires high-quality LCD modules capable of mirroring mobile device interfaces seamlessly.

Advanced infotainment LCD modules often incorporate split-screen functionality that allows users to access multiple applications simultaneously, such as navigation and media playback or climate control and communication features. The responsiveness of these systems depends heavily on the quality of the underlying LCD module technology, including touch sensitivity, color accuracy, and refresh rates that ensure smooth operation of complex graphical interfaces and real-time content updates.

Safety and Performance Considerations

Enhanced Driver Safety Through Visual Information Systems

Automotive LCD modules play a vital role in enhancing driver safety by providing clear, immediate access to critical vehicle information and environmental awareness features. Rear-view camera systems, blind-spot monitoring displays, and parking assistance interfaces all rely on high-quality LCD modules to present visual information that helps drivers make informed decisions in challenging situations. The clarity and response time of these displays can significantly impact their effectiveness in preventing accidents and improving overall road safety.

Night vision systems and thermal imaging displays represent advanced safety applications that require specialized LCD modules capable of presenting infrared and enhanced imagery clearly and accurately. These systems help drivers detect pedestrians, animals, and obstacles beyond the range of traditional headlights, particularly during low-visibility conditions. The integration of heads-up display technology with LCD modules creates additional safety benefits by projecting essential information directly into the driver's line of sight without requiring them to look away from the road.

Durability and Reliability Standards

Automotive LCD modules must meet stringent reliability standards that far exceed those required for consumer electronics, given the harsh environmental conditions and critical safety applications in which they operate. Vibration resistance, temperature cycling capability, and electromagnetic interference protection represent fundamental requirements that influence both design and manufacturing processes. These modules undergo extensive testing protocols that simulate years of automotive use under various conditions to ensure long-term reliability.

The automotive qualification process for LCD modules typically includes accelerated aging tests, thermal shock evaluations, and mechanical stress assessments that verify performance across the entire operational temperature range. Moisture resistance and chemical compatibility testing ensure that these displays can withstand exposure to automotive fluids and environmental contaminants without degradation. Quality assurance protocols also address pixel defect rates, color stability over time, and backlight longevity to guarantee consistent performance throughout the vehicle's operational lifetime.

Integration Challenges and Solutions

Electromagnetic Compatibility and Interference Management

The integration of LCD modules in automotive environments presents unique challenges related to electromagnetic interference from various vehicle systems, including ignition systems, radio transmissions, and electric motor operations. Proper shielding and grounding techniques become essential to prevent display artifacts, touch sensitivity issues, and communication disruptions that could compromise system functionality. Advanced LCD modules incorporate sophisticated filtering and isolation measures to maintain performance in electrically noisy automotive environments.

Design considerations for electromagnetic compatibility extend beyond the LCD module itself to include cable routing, connector specifications, and integration with vehicle wiring harnesses. Proper installation techniques and adherence to automotive electromagnetic compatibility standards ensure that LCD modules do not interfere with other vehicle systems while maintaining their own operational integrity. These considerations become particularly important in electric and hybrid vehicles where high-voltage systems create additional electromagnetic challenges.

Power Management and Energy Efficiency

Automotive LCD modules must operate efficiently within vehicle power systems that experience significant voltage variations and potential interruptions during engine start-stop cycles. Advanced power management circuits within these modules regulate voltage levels, manage startup sequences, and implement energy-saving features that reduce overall power consumption. Backlight dimming controls and automatic sleep modes help preserve battery life while maintaining display functionality when needed.

The integration of LCD modules with vehicle power management systems requires careful consideration of startup priorities, shutdown sequences, and emergency power allocation protocols. These displays often need to maintain basic functionality during low-power conditions while providing critical information during vehicle startup and shutdown procedures. Energy efficiency improvements in LED backlighting technology have significantly reduced power consumption while improving brightness and color quality compared to older fluorescent-based systems.

Future Developments and Emerging Technologies

Next-Generation Display Technologies

The future of automotive LCD modules involves the integration of emerging display technologies such as quantum dot enhancement, mini-LED backlighting, and flexible substrate materials that enable curved and conformable display surfaces. These advanced technologies promise improved color gamut, higher contrast ratios, and design flexibility that allows for more creative integration approaches within vehicle interiors. Quantum dot technology specifically offers enhanced color accuracy and efficiency that can improve both visual quality and power consumption characteristics.

Flexible and curved LCD modules represent significant opportunities for automotive designers to create more ergonomic and aesthetically pleasing interior layouts while maintaining the functional advantages of traditional flat-panel displays. These technologies enable the creation of wraparound dashboard displays, integrated door panel interfaces, and seamless integration with vehicle trim elements. The development of transparent and semi-transparent LCD modules also opens possibilities for augmented reality applications and heads-up display integration.

Artificial Intelligence and Adaptive Interfaces

The integration of artificial intelligence capabilities with automotive LCD modules enables the development of adaptive interfaces that learn from user behavior and preferences to optimize information presentation and system responsiveness. Machine learning algorithms can analyze driving patterns, frequently accessed functions, and environmental conditions to automatically adjust display configurations and prioritize relevant information. These smart systems can also predict user needs and pre-load relevant information or applications based on context and historical usage patterns.

Voice recognition integration with LCD modules creates multimodal interaction capabilities that allow users to control displays through spoken commands while receiving visual feedback and confirmation. Natural language processing advances enable more sophisticated communication between users and vehicle systems, with LCD modules serving as the primary visual interface for displaying system responses, configuration options, and status information. The combination of touch, voice, and gesture recognition creates more intuitive and safer interaction methods for vehicle occupants.

FAQ

What makes automotive LCD modules different from standard consumer displays

Automotive LCD modules are specifically engineered to withstand extreme temperature variations, constant vibration, electromagnetic interference, and prolonged exposure to sunlight while maintaining consistent performance. They incorporate specialized materials, enhanced backlighting systems, and ruggedized construction techniques that far exceed the durability requirements of typical consumer electronics. Additionally, automotive LCD modules must meet stringent safety and reliability standards established by the automotive industry, including extensive testing protocols that simulate years of vehicle operation under various environmental conditions.

How do LCD modules improve vehicle safety features

LCD modules enhance vehicle safety by providing clear, real-time visual information for critical safety systems including rear-view cameras, blind-spot monitoring, parking assistance, and collision warning systems. These displays present essential information with optimal clarity and rapid response times that help drivers make quick decisions in potentially dangerous situations. Advanced LCD modules also support heads-up display technology that projects important information directly into the driver's line of sight, reducing the need to look away from the road while accessing critical vehicle and navigation data.

What resolution and size options are available for automotive LCD modules

Automotive LCD modules are available in a wide range of sizes from small instrument cluster displays measuring just a few inches to large infotainment screens exceeding fifteen inches diagonally. Resolution options span from basic VGA displays for simple applications to Full HD and higher resolutions for advanced infotainment and navigation systems. The choice of size and resolution depends on the specific application, viewing distance, and the complexity of information being displayed, with larger, higher-resolution modules typically used for infotainment systems and smaller, more focused displays used for instrument clusters and specialized indicators.

How long do automotive LCD modules typically last in vehicle applications

High-quality automotive LCD modules are designed to operate reliably for the entire operational lifetime of the vehicle, typically ranging from ten to fifteen years or more under normal usage conditions. The longevity of these displays depends on factors such as operating temperature ranges, usage patterns, and exposure to environmental stresses, but proper automotive-grade modules incorporate enhanced materials and construction techniques that ensure consistent performance over extended periods. Regular software updates and proper maintenance can help maximize the operational lifespan of these critical display components while maintaining optimal functionality throughout the vehicle's service life.